In the ever-evolving landscape of electronics manufacturing, the demand for speed, precision, and consistency has never been higher. As industries strive to produce compact, efficient, and high-performing devices, surface-mount technology (SMT) plays a vital role. At the heart of SMT lies the specialized machine responsible for placing surface-mounted devices (SMDs) onto printed circuit boards (PCBs). NECTEC, a leader in technological innovation, provides state-of-the-art chip mounter solutions that cater to the diverse needs of modern electronics production. With a sharp focus on performance, NECTEC’s deliver unmatched speed, accuracy, and reliability.

Understanding the Role of a Chip Mounter

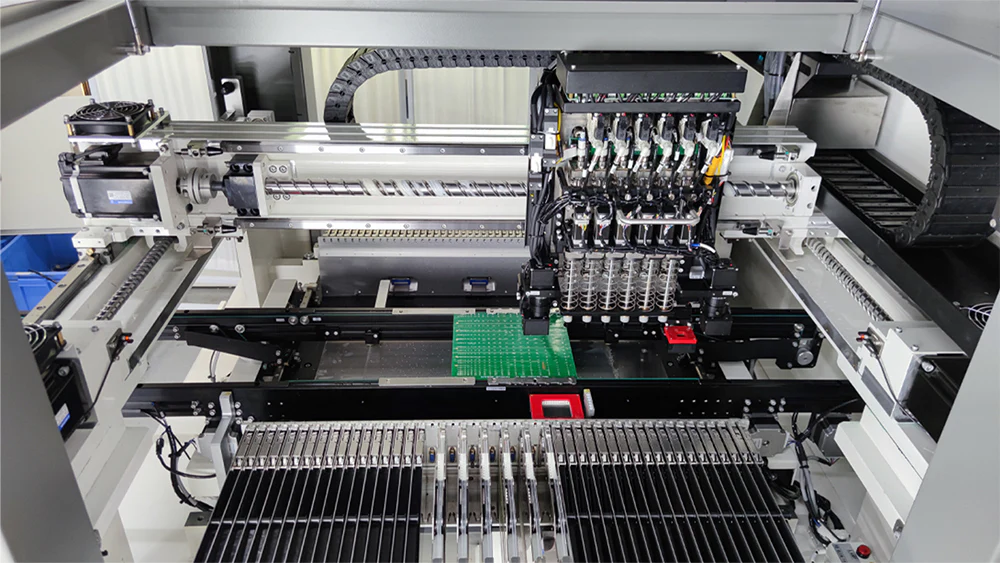

A chip mounter, also known as a pick-and-place machine, automates the process of placing electronic components onto PCBs. This step is critical in the SMT process, as even the slightest misalignment or placement error can compromise the functionality of the final product. It must operate with high precision and at incredible speeds to keep up with today’s high-volume production lines. NECTEC’s solutions are engineered to meet these demands without sacrificing quality or flexibility.

Why Choose NECTEC Chip Mounter Solutions

Industry-Leading Accuracy

Accuracy is paramount in the SMT process, and NECTEC’s are equipped with advanced vision systems and alignment algorithms. These features ensure precise component placement, even for the smallest and most complex SMDs. This level of accuracy minimizes defects and enhances the overall reliability of electronic assemblies.

High-Speed Operation

Time is money in electronics manufacturing. NECTEC’s solutions are designed for maximum throughput, capable of placing tens of thousands of components per hour. This efficiency helps manufacturers meet tight deadlines and scale production without compromising on quality.

Exceptional Reliability

In a production environment, downtime translates to lost revenue. NECTEC are built with high-quality components and undergo rigorous testing to ensure long-term performance. With minimal maintenance requirements and robust mechanical designs, these machines are trusted by manufacturers worldwide.

User-Friendly Interface

One of the standout features of NECTEC’s chip mounter solutions is their intuitive software interface. Operators can quickly configure placement parameters, run diagnostics, and monitor performance in real-time. The software is also designed to integrate seamlessly with other SMT systems, supporting a cohesive manufacturing process.

Scalable Solutions for Every Production Need

NECTEC offers a wide range of chip mounter models to suit varying levels of production, from prototype development to full-scale manufacturing. Whether you are a small business venturing into electronics or a global enterprise with high-volume requirements, NECTEC has solution tailored to your needs.

Advanced Technologies Integrated in NECTEC Chip Mounters

Vision Alignment Systems

NECTEC’s chip mounters utilize high-resolution cameras and optical sensors to ensure perfect alignment during component placement. These vision systems automatically detect component orientation, adjust placement coordinates, and verify accuracy in real-time, drastically reducing the chance of placement errors.

Smart Feeder Systems

Component feeders are essential for uninterrupted operation. NECTEC chip mounters are equipped with intelligent feeder systems that detect low inventory, identify misfeeds, and enable rapid reloading. These systems improve uptime and help prevent costly production halts.

Real-Time Monitoring and Data Analytics

Modern manufacturing requires continuous oversight. NECTEC’s offer real-time monitoring capabilities, with detailed analytics on placement accuracy, throughput, and equipment health. This data-driven approach allows manufacturers to fine-tune their processes and maintain high yield rates.

Integration with Industry 4.0

NECTEC embraces Industry 4.0 principles by enabling smart factory integration. Their chip mounters can be connected to MES (Manufacturing Execution Systems), ERP software, and other automation tools. This connectivity enables seamless communication between machines and better resource planning across the factory floor.

Applications of NECTEC Chip Mounter Solutions

Consumer Electronics

In smartphones, tablets, and wearable technology, components are densely packed and require precise placement. NECTEC’s chip mounters are ideal for this sector due to their high-resolution placement capabilities and rapid throughput.

Automotive Electronics

With the rise of electric vehicles and smart automotive systems, the need for durable and accurately placed components has grown. NECTEC’s chip mounters help meet these requirements with their reliable performance in harsh manufacturing environments.

Medical Devices

Medical electronics demand stringent compliance with safety and accuracy standards. NECTEC solutions provide the precision and quality control necessary for assembling sensitive medical devices.

Industrial Equipment

Industrial systems require robust electronics to manage operations in challenging conditions. NECTEC chip mounters support the production of rugged, reliable electronics for industrial automation and control systems.

Advantages for Manufacturers

Cost Efficiency

By minimizing placement errors and reducing downtime, NECTEC’s chip mounter solutions help lower manufacturing costs. The high-speed placement and low maintenance requirements also reduce labor and operational expenses over time.

Quality Assurance

NECTEC’s chip mounters are equipped with inspection systems that monitor every component during placement. This real-time quality assurance helps catch defects early and maintain product integrity throughout the manufacturing cycle.

Faster Time-to-Market

With quick setup times and efficient changeovers, NECTEC chip mounters enable manufacturers to respond rapidly to market changes. New product introductions can be handled with ease, accelerating time-to-market and providing a competitive edge.

NECTEC’s Commitment to Innovation

As a pioneer in electronics manufacturing technologies, NECTEC continuously invests in research and development to enhance its chip mounter solutions. Their dedicated engineering teams work closely with clients to identify emerging needs and deliver customized innovations. This commitment to excellence ensures that NECTEC remains at the forefront of SMT automation.

Customer Support and Training

Buying a chip mounter is a significant investment, and NECTEC ensures that clients receive full value. They offer comprehensive training programs, technical documentation, and ongoing support to keep equipment running at peak performance. From installation to troubleshooting, NECTEC’s support team is available to guide users every step of the way.

Sustainable Manufacturing Practices

In an era of increasing environmental awareness, NECTEC aligns its operations with sustainable manufacturing practices. Their chip mounter solutions are designed for energy efficiency and minimal waste. Additionally, the company promotes eco-friendly packaging and recycling protocols to support green manufacturing goals.

Frequently Asked Questions

What is a chip mounter and why is it important?

A chip mounter is a machine used in electronics manufacturing to accurately place surface-mounted devices on printed circuit boards. It is essential for ensuring precision, speed, and consistency in assembling modern electronic devices.

How does NECTEC ensure the accuracy of its chip mounters?

NECTEC chip mounters use advanced vision alignment systems and precision engineering to ensure accurate placement of components. Real-time monitoring and data analytics further enhance their reliability.

Can NECTEC chip mounters be used in low-volume production environments?

Yes, NECTEC offers scalable chip mounter solutions suitable for both low-volume prototyping and high-volume mass production. Their flexible platforms cater to a wide range of manufacturing needs.

Conclusion

In today’s competitive electronics manufacturing sector, speed, precision, and dependability are crucial. NECTEC’s chip mounter solutions embody these values, offering a perfect balance between cutting-edge technology and practical usability. With advanced features, unmatched performance, and exceptional support, NECTEC is the go-to partner for manufacturers seeking to optimize their SMT processes.

Explore our homepage now to stay ahead in the digital world.

Whether you’re building consumer electronics, automotive components, or medical devices, NECTEC chip mounters provide the foundation for high-quality, efficient production. Invest in NECTEC’s chip mounter solutions and elevate your manufacturing capabilities to new heights.