Hydraulic systems are the backbone of many industrial and construction operations. From excavators to manufacturing presses, these machines rely on high-pressure fluid systems to function. But when these systems fail, operations can grind to a halt. That’s where on-site hydraulic repair becomes a game-changer. Rather than removing equipment for off-site servicing, on-site solutions offer quick and cost-effective fixes. In this article, we explore nine proven on-site hydraulic repair techniques that can help you restore productivity fast and reduce downtime.

Why Choose On-Site Hydraulic Repair?

On-site hydraulic repair offers numerous benefits compared to traditional shop repairs. First, it eliminates the need to transport heavy machinery, saving time and logistics costs. Second, technicians can diagnose and address issues directly in the system’s operating environment, ensuring repairs are both relevant and efficient. Third, downtime is significantly reduced because many repairs can be done within hours rather than days.

At RHK Hydraulic Cylinder Services, our on-site hydraulic repair experts are trained to provide rapid diagnostics, precision fixes, and long-lasting solutions without compromising safety or system integrity.

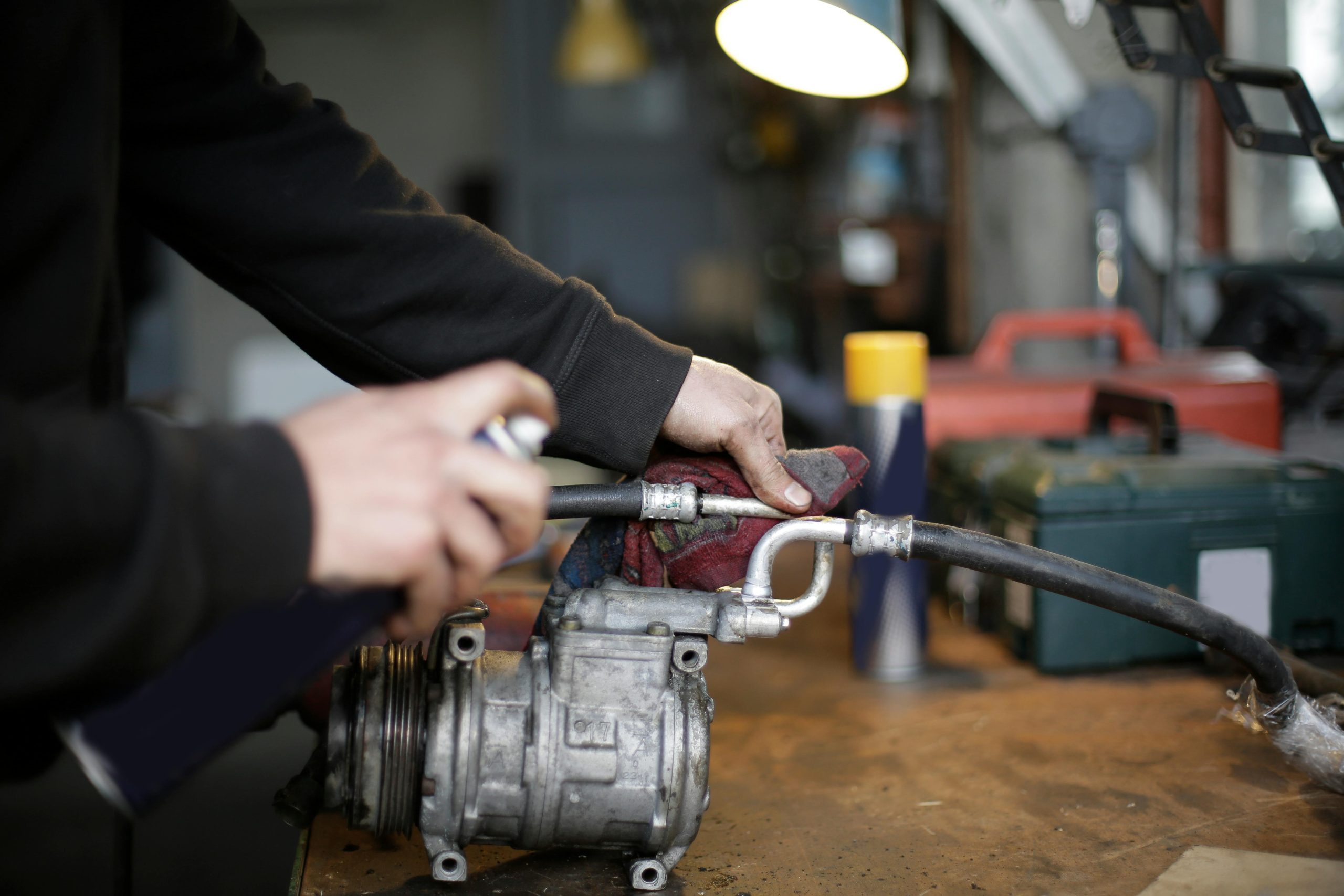

1. Hose Replacement on the Spot

One of the most common issues in hydraulic systems is a damaged or leaking hose. A ruptured hose can instantly bring operations to a standstill. On-site hydraulic repair teams carry a wide variety of hose types and fittings, allowing them to replace faulty hoses immediately. Using portable crimping machines, the new hose can be custom-fitted to match OEM specifications, ensuring durability and efficiency.

2. Cylinder Seal Replacement

Hydraulic cylinders are crucial components that often suffer from worn or damaged seals. When seals fail, they cause internal or external leakage, reducing performance and increasing safety risks. On-site technicians can disassemble the cylinder, replace seals, and reassemble the unit without needing to send it offsite. This quick intervention restores performance and prevents further damage.

3. Valve Troubleshooting and Repair

Control valves regulate fluid flow within a hydraulic system. Malfunctions such as sticking spools, internal leakage, or contamination can lead to sluggish or unpredictable system responses. With on-site hydraulic repair, technicians can clean or replace valves, recalibrate them if needed, and test the system in real-time to ensure optimal operation.

4. Hydraulic Fluid Analysis and Replacement

Contaminated or degraded hydraulic fluid can lead to excessive wear and premature component failure. An essential part of on-site hydraulic repair includes fluid analysis. Experts use diagnostic tools to check for contamination, viscosity, and water content. If needed, the old fluid is flushed out and replaced with fresh, high-quality hydraulic oil, restoring system health and performance.

5. Pressure Testing and Leak Detection

Low system pressure is a red flag that something isn’t right. On-site hydraulic repair specialists use pressure gauges and flow meters to locate pressure drops and pinpoint leaks. Whether it’s a faulty seal, a cracked fitting, or internal bypassing, once the root cause is identified, targeted fixes are applied immediately to restore optimal pressure levels.

6. Component Re-Torquing

Over time, bolts and fittings in hydraulic systems can loosen due to vibration and thermal expansion. This can cause leaks or misalignment in the system. On-site hydraulic repair includes re-torquing all critical components to their specified settings. Using torque wrenches and calibration tools, technicians ensure that every part is securely fastened and aligned to prevent future failures.

7. Filter Replacement

Hydraulic filters are designed to trap contaminants, but once clogged, they become a source of system inefficiency. As part of an on-site hydraulic repair, filters are inspected and replaced if needed. Regular filter maintenance reduces system strain and extends the life of hydraulic components.

8. Pump and Motor Diagnostics

The hydraulic pump and motor are central to system performance. Issues like cavitation, overheating, or inconsistent flow can signal deeper problems. On-site diagnostics can evaluate the pump’s output, temperature, and condition. If repair or adjustment is needed, technicians can perform it immediately, minimizing downtime and preventing catastrophic failures.

9. Emergency Hydraulic Line Repairs

Unexpected line failures require urgent attention. Whether from corrosion, mechanical damage, or excessive pressure, a broken line can halt operations. On-site hydraulic repair technicians can isolate the failure, cut and replace damaged lines, and restore flow using mobile flaring, bending, or welding tools. These quick-response fixes can mean the difference between hours and days of lost productivity.

Why RHK Hydraulic Cylinder Services is the Right Choice

At RHK Hydraulic Cylinder Services, we understand the value of uptime. Our certified field technicians are equipped with advanced diagnostic tools, replacement parts, and the experience to handle any hydraulic emergency. With decades of experience in on-site hydraulic repair, we specialize in restoring performance quickly and reliably, ensuring your business stays operational.

We pride ourselves on:

- Rapid response times

- OEM-level part replacements

- Custom solutions tailored to your equipment

- 24/7 availability for emergency situations

- Transparent pricing with no hidden fees

Frequently Asked Questions

Q1: How do I know if I need on-site hydraulic repair or off-site service?

If your equipment is too large or expensive to transport, or if the issue is urgent and causing downtime, on-site hydraulic repair is ideal. Our technicians can diagnose the situation and recommend the best course of action.

Q2: How long does an average on-site hydraulic repair take?

Most repairs can be completed within a few hours, depending on the complexity of the issue. We aim to minimize downtime while ensuring a thorough, lasting fix.

Q3: Is on-site hydraulic repair more expensive than off-site service?

While on-site repairs may seem more expensive upfront due to travel and equipment costs, the reduction in downtime and transport costs usually makes it more cost-effective overall.

Conclusion

Hydraulic systems are critical to the efficiency of your operations. When problems arise, swift and reliable intervention is key. With the expertise of RHK Hydraulic Cylinder Services, you can rely on efficient on-site hydraulic repair to restore power, reduce downtime, and prevent costly breakdowns. Whether it’s a leaking hose, a failing seal, or a clogged filter, the nine proven fixes outlined in this article can help you address issues quickly and confidently.

Explore our homepage now to stay ahead in the digital world.