In today’s fast-paced world, protecting mobile devices is more important than ever. With the increasing demand for customized and precise screen protectors, the screen protector machine has become an essential tool for manufacturers and retailers alike. Whether you’re a business owner aiming to enhance product quality or a tech enthusiast seeking perfection, understanding the capabilities of a screen protector machine can revolutionize how you approach mobile protection.

This article delves deep into what makes the Screen protector machine a game-changer, highlighting its benefits, working mechanism, types, and why investing in one is a smart move for flawless mobile cuts.

What Is a Screen Protector Machine?

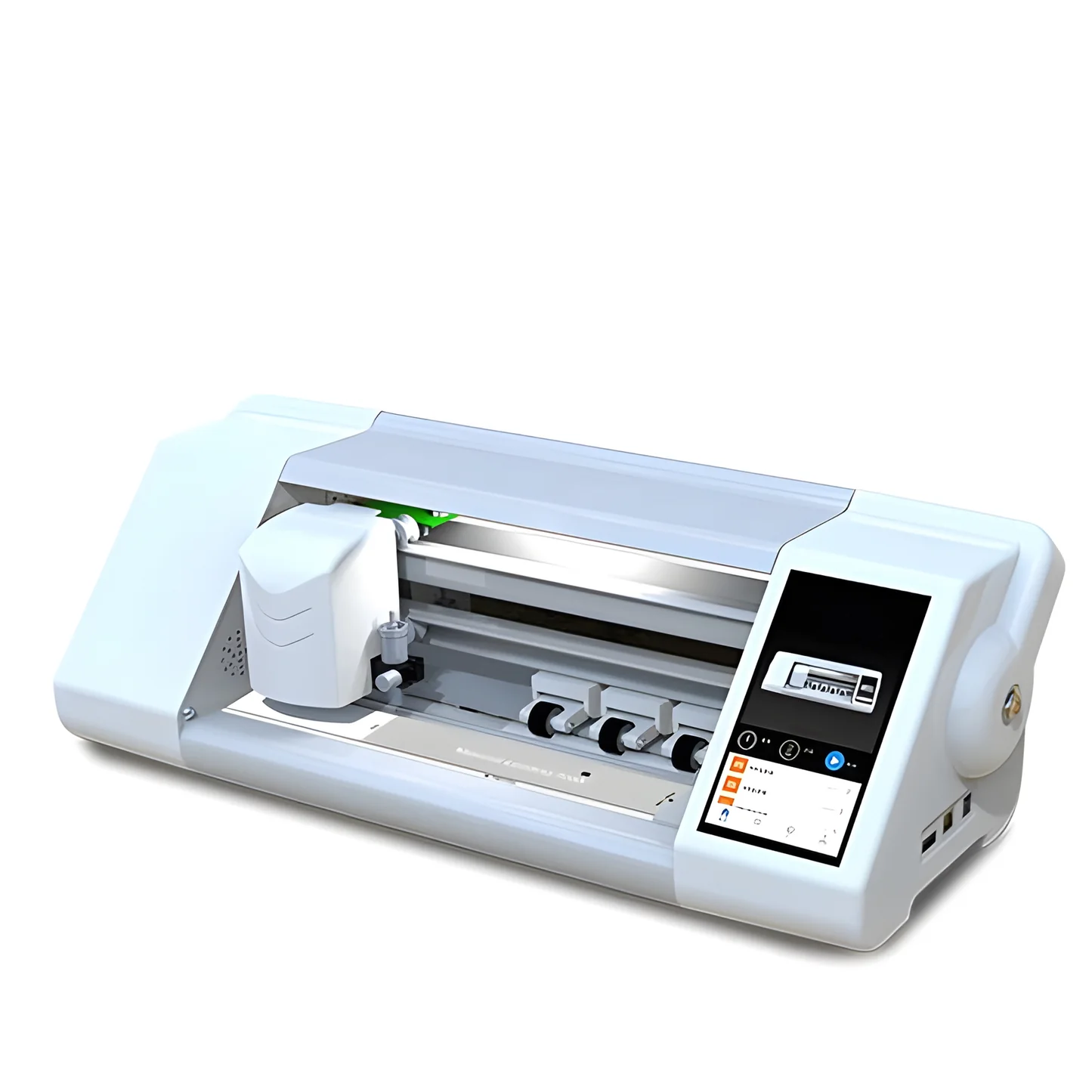

A screen protector_ machine is a specialized cutting device designed to produce precise, clean, and custom-shaped screen protectors for various mobile devices. Unlike manual cutting or standard die-cut machines, this equipment uses advanced technology—such as laser cutting, CNC routing, or precision blade systems—to ensure every protector perfectly fits the mobile device’s screen.

The importance of accuracy in screen protector manufacturing cannot be overstated. Even minor errors in cutting can lead to poor fit, bubbles, peeling, or reduced touch sensitivity. Hence, a screen protector_ machine is indispensable for achieving flawless mobile cuts consistently.

Why Choose a Screen Protector Machine?

1. Precision and Accuracy

The primary advantage of a screen protector_ machine is its ability to deliver precise cuts tailored to the exact dimensions of any mobile device. This precision minimizes waste and ensures that protectors fit perfectly, reducing customer complaints and returns.

2. Enhanced Efficiency

Manual cutting is time-consuming and prone to errors. A screen protector_ machine automates the process, significantly increasing production speed while maintaining consistent quality.

3. Versatility

These machines can handle various materials, including tempered glass, PET, TPU, and other film types. They can produce protectors for smartphones, tablets, and even wearables, making them versatile assets for any manufacturing line.

4. Cost-Effective in the Long Run

Though the initial investment may seem high, the screen protector machine reduces labor costs and material waste, offering excellent returns over time.

Types of Screen Protector Machines

Laser Cutting Machines

Laser cutting machines use focused laser beams to cut through screen protector materials with extreme precision. They produce smooth edges and can cut complex shapes, including camera holes and sensor cutouts, without damaging the material.

CNC Cutting Machines

Computer Numerical Control (CNC) machines use precise mechanical tools guided by computer software to carve out screen protectors. These machines are highly accurate and can be programmed for different device models.

Die-Cutting Machines

Die-cutting is a traditional method where a shaped die stamps the protector material. While fast for mass production, it lacks the flexibility and precision of laser or CNC machines, making it less ideal for customized or intricate cuts.

How Does a Screen Protector Machine Work?

A screen protector machine typically works by following these steps:

- Design Input: The device’s exact screen dimensions and cutout details are input into the machine software.

- Material Placement: The protective film or glass sheet is loaded onto the machine’s cutting platform.

- Cutting Process: Using lasers, blades, or routers, the machine cuts the screen protector according to the design, creating clean, precise edges.

- Quality Check: Finished protectors are inspected for accuracy and defects before packaging.

This automated workflow ensures minimal human error and consistent output quality.

Benefits of Using a Screen Protector Machine for Your Business

Superior Product Quality

Businesses leveraging a screen protector machine can guarantee a perfect fit, improving customer satisfaction and brand reputation.

Faster Turnaround Time

With automation, manufacturers can meet high demand without compromising quality, essential in today’s competitive market.

Customization Capability

New phone models hit the market frequently. Screen protector machines can quickly adapt to new designs, helping businesses stay ahead.

Reduced Material Waste

Precise cutting means less wasted film or glass, lowering production costs and environmental impact.

Choosing the Right Screen Protector Machine

When selecting a screen protector machine, consider the following:

- Cutting Technology: Laser or CNC machines offer better precision than die-cutting.

- Compatibility: Ensure the machine supports the materials you plan to use.

- Production Capacity: Match the machine’s speed with your business needs.

- Software Integration: Look for machines with user-friendly software for easy design input.

- Maintenance and Support: Opt for brands with reliable customer support and maintenance services.

Maintaining Your Screen Protector Machine

Proper maintenance prolongs the life and efficiency of your machine:

- Regularly clean cutting surfaces and blades.

- Update software to incorporate new device designs.

- Schedule professional servicing as recommended by the manufacturer.

- Store the machine in a dust-free environment.

The Future of Screen Protector Machines

As technology advances, screen protector machines are integrating AI and machine learning to further enhance precision and efficiency. Automated defect detection and real-time adjustment systems are becoming standard, promising even more flawless mobile cuts in the near future.

Conclusion: Why a Screen Protector Machine is Essential for Flawless Mobile Cuts

A screen protector machine is a vital investment for anyone serious about producing high-quality, perfectly fitting screen protectors. Its precision, efficiency, and adaptability make it indispensable in the competitive mobile accessory industry. Whether you’re scaling your production or enhancing product quality, this machine ensures every mobile screen protector you produce meets the highest standards. Embrace the technology today and experience flawless mobile cuts that delight customers and elevate your brand. From expert tips to trending updates, it’s all available on our main page.

Frequently Asked Questions (FAQ)

Q1: Can a screen protector machine cut protectors for all phone models?

Yes, most modern screen protector machines are highly adaptable and can be programmed to cut protectors for a wide range of phone models, including new releases.

Q2: Is it difficult to operate a screen protector machine?

Not at all. These machines typically come with intuitive software and user-friendly interfaces, making them accessible even for those without extensive technical knowledge.

Q3: How much maintenance does a screen protector machine require?

Maintenance varies by machine type but generally includes cleaning cutting components, updating software, and occasional professional servicing to ensure optimal performance.